Top and Bottom Labeling Systems

When it comes to labeling solutions, top and bottom labeling systems are some of the most commonly used. It provides a quick and easy way to apply variable data to packages. For example, food packages may need different expiration dates, ingredient lists, or batch numbers. These types of requirements can complicate the production process, but top and bottom labeling systems are able to manage these tasks and make the packaging process more efficient.

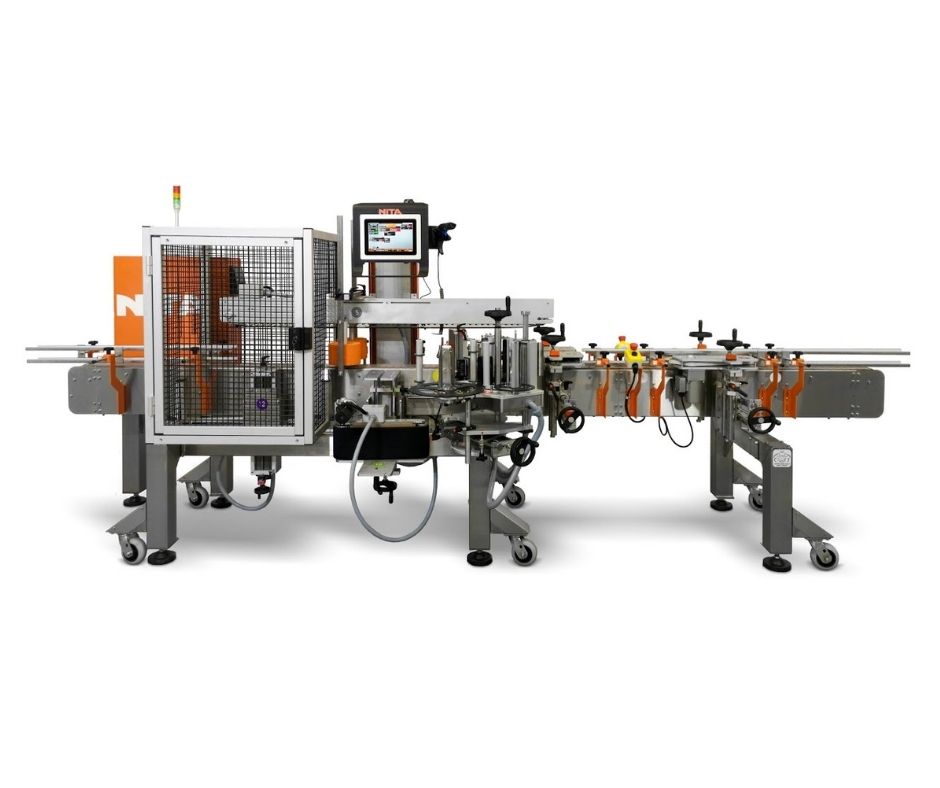

Powerful And Versatile Label Machine For Front Or Multi-Panel Labeling

Machine Type: Front and back label machine

Label Applications: Front and back labeling, multi-panel labeling, full wrap labeling

Container Types: Label machine applies labels to plastic, glass, bottles, paper, cardboard, metal, round bottles, vials, and most other materials

Built for speed, precision and extreme simplicity of operation, the XP200T labeling machine is engineered to perform with maximum productivity and uptime in mind.

Redundant Retractable Labeling Heads.

Automatic Depleted Label Roll Switchovers.

Call us NOW to learn more about this and all of the other game-changing features you will only find on a Nita Sentient Labeling System.

1-855-668-NITA (6482) or email if you prefer at sales@nita.ca.

Powerful And Versatile Labeler For Front Or Multi-Panel Labeling Of Buckets, Pails, Jugs And Tubs

Machine Type: Pail labeling machine, pail labeler, bucket labeler

Labeling Applications: Front labeling, multi-panel labeling, full wrap labeling

Container Types: Labels round or square plastic buckets, jugs, pails, tubs, metal and most other materials

Built for speed, precision and extreme simplicity of operation, the XP Pail Series of labeling machine is engineered to perform with maximum productivity and uptime in mind.

Top and bottom labeling systems are used for both primary and secondary packaging. The label can be accurately applied to either the top or the bottom of the package as required. Additional outer cardboard boxes can also be affixed with the proper label. Packaging and labeling possibilities also extend to all sorts of different materials. Frozen food packages, plastic containers, aluminum cans, and glass bottles can all be perfectly positioned in the labeling machine and accurately labeled.

Being able to print variable information on labels is often a priority for companies. This means that they have to be able to program the labeling system and have the machine execute the commands correctly. Fortunately, this process is made easy and user-friendly with the help of touch screen controls. A few taps on the screen will allow you to program the labeler and provide any other instructions. You can start and stop labeling as needed and use the screen will communicate any important messages as it monitors the labeling process.

Label sensors help with quality control. Depending on the equipment you are using, there will be any number of sensors throughout the machine that work to monitor the labeling process. It will alert you if there was a missed label or a product has been double-labeled. The product with the missing or defective label can be automatically removed from the production line without having to pause the labeling process. This means that you can more efficiently and accurately label your products.

With top and bottom labelers, conveyor speed is a major concern. Depending on your product, you should be looking for a conveyor speed of between 100 to 250 units per minute. The labeling will be able to maintain this speed while also dispensing and applying labels in a precise manner with little to no deviation in placement.

Most top and bottom labeling machines are made even more convenient through the use of pressure-sensitive labels. With this technology, a label is dispensed and then blown into place where it is tamped down with the right amount of pressure. This is all it takes to activate the adhesive and ensure a tight bond that will stay in place throughout the transportation and distribution process. No matter how far your products have to travel to make it to a retail location or delivery destination, they will arrive looking clean and professional.

Not only do top and bottom labelers help show your brand in a professional light with well-designed and accurately applied labels, but they also provide tremendous value to your business. Investing in a top and bottom labeling machine