Front and Back Labeling Machines

Front and back labeling machines are designed to label both sides of a package. While they are commonly used on oval or irregularly shaped containers, they can also tackle rectangular products and apply two or more labels to the container. Basically, they can apply multiple labels to almost any type of container, making them a valuable asset to a wide range of industries.

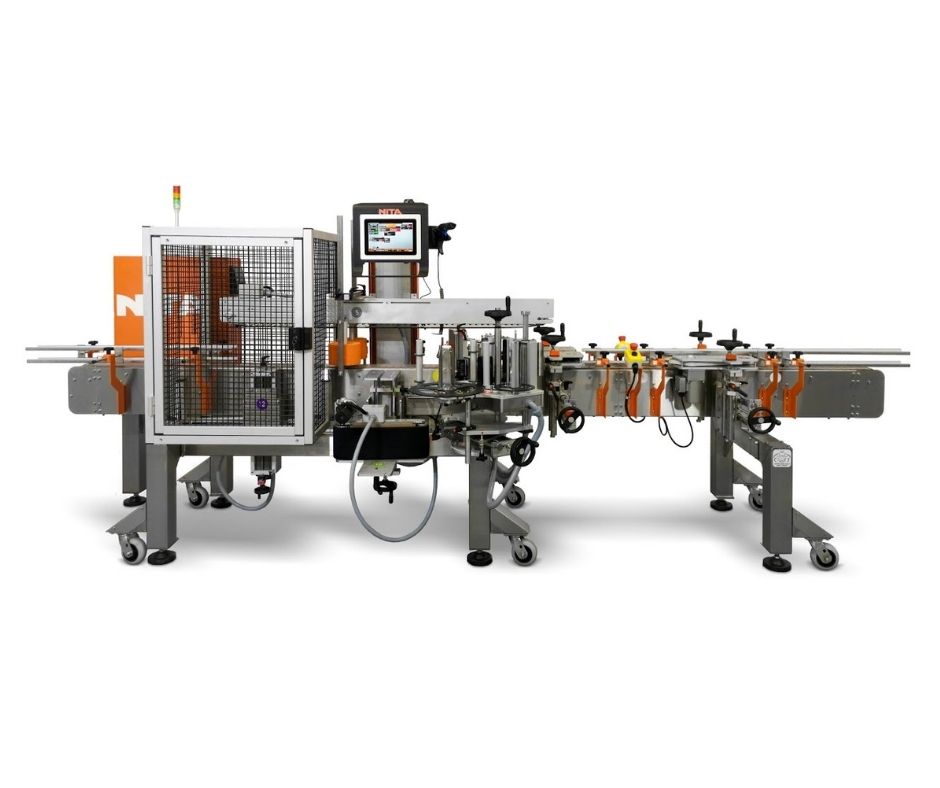

Powerful And Versatile Label Machine For Front Or Multi-Panel Labeling

Machine Type: Front and back label machine

Label Applications: Front and back labeling, multi-panel labeling, full wrap labeling

Container Types: Label machine applies labels to plastic, glass, bottles, paper, cardboard, metal, round bottles, vials, and most other materials

Built for speed, precision and extreme simplicity of operation, the XP200T labeling machine is engineered to perform with maximum productivity and uptime in mind.

Redundant Retractable Labeling Heads.

Automatic Depleted Label Roll Switchovers.

Call us NOW to learn more about this and all of the other game-changing features you will only find on a Nita Sentient Labeling System.

1-855-668-NITA (6482) or email if you prefer at sales@nita.ca.

Powerful And Versatile Labeler For Front Or Multi-Panel Labeling Of Buckets, Pails, Jugs And Tubs

Machine Type: Pail labeling machine, pail labeler, bucket labeler

Labeling Applications: Front labeling, multi-panel labeling, full wrap labeling

Container Types: Labels round or square plastic buckets, jugs, pails, tubs, metal and most other materials

Built for speed, precision and extreme simplicity of operation, the XP Pail Series of labeling machine is engineered to perform with maximum productivity and uptime in mind.

Printing and attaching wine labels is just one example of using front and back labels. The printer can accurately and efficiently print and apply labels to bottles, easily handling the cylindrical shape. This allows brands to display their logo while also providing important information on the back of the bottle. These labelers can also be programmed to print and apply wrap-around labels if necessary.

Labeling is an important part of the production process and one area where valuable time can be lost. Manually labeling products is a time-consuming process that uses up expensive man-hours. With a front and back printing and labeling machine, you can exponentially speed up the labeling process and have the ability to precisely label hundreds of products per hour. That allows you to keep up with demand and make sure that customers have access to your products and better utilize your employees. Their time and energy can be redirected to more important tasks that will impact the success and growth of the company.

Some companies are hesitant to invest in a front and back label machine because it requires an upfront investment. That is why it is important to consider the overall value of purchasing a labeling machine. The ability to increase production and work more efficiently while also improving the accuracy of your labeling will quickly provide a return on investment.

In addition, front and back printing and labeling machines are designed to be durable and withstand repetitive use in a variety of environments. With monitoring features, you can stay up-to-date on the health of your machinery and prevent any labeling mistakes. Partnering with the right manufacturer also means that you will have quick and easy access to support. If necessary, an experienced technician can be dispatched to your location to troubleshoot and reduce unnecessary downtime.

Fortunately for today’s businesses, front and back bottle labeling machines offer a wide range of options so that you can find a model that fits your needs and your budget. There are models that provide a smaller footprint and various dispensing and conveyor speeds. You can also choose from different fully automatic and semi-automatic machines. Smaller operations may find that incorporating a lower level of automation is enough to effectively ramp up production.

Perhaps best of all, these machines are designed to grow and scale with your company. New capabilities can be added without having to purchase an entirely new machine. For example, you can start with a front and back labeler and eventually install a modular that can handle wrap-around labels when needed. These are versatile machines that will adapt as needed.

One of the features that make the front and back label applicators so valuable is the use of pressure-sensitive adhesive. You don’t have to worry about having to activate the adhesive with heat or water. The right amount of pressure is enough to ensure a secure bond. The labels won’t become loose during the transit or stocking processes and you can feel confident that your products look great and attract customers.

No matter what type of product you sell or what size and shape container it is packaged in, there is a label printing and applicator machine that will allow you to efficiently apply labels to both the front and back. SheaPak can help design and install the perfect front and back label applicator to fit your brand’s goals both short-term and long-term.